EcoGrete™ In Action: Building a Sustainable Future

Discover PolyQor's groundbreaking projects, showcasing how EcoGrete™ sustainable aggregates are transforming construction worldwide. Join us in building a more resilient and circular future.

Our Global Showcase of Sustainable Construction

PolyQor is at the forefront of sustainable construction, delivering innovative projects across the globe. Our EcoGrete™ aggregates are proving their worth in real-world applications, reducing environmental impact while maintaining high performance standards.

We invite you to explore our portfolio and witness the tangible benefits of sustainable building materials. Each project is a testament to our commitment to a greener planet.

Project Studies: Building a Circular Future

Our detailed case studies highlight the innovative application of EcoGrete™ in various construction sectors. Each study provides insights into the challenges overcome and the sustainable benefits achieved.

Detailed Project Studies: Pakistan

PolyQor has made significant strides in Pakistan, implementing EcoGrete™ in a range of impactful projects. Our commitment to sustainable development is evident in every structure.

PROJECT STUDY #001

Shell - PF Malik

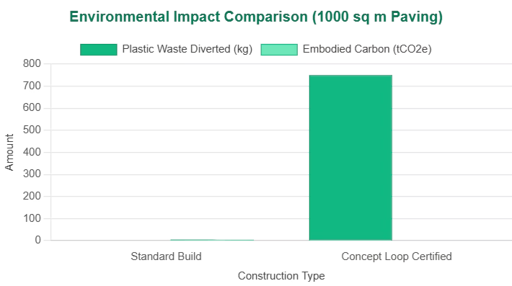

Concept Loop together with Shell Pakistan have made Pakistan’s 1st retail site with recycled plastic waste. The construction of the retail site utilized approximately 6,500 kilograms, or roughly 1.3 million pieces, of end-of-life plastic waste, in plastic infused pavers and concrete blocks using multi layered plastic waste. According to research, a simple plastic bag can take up to 500 years to decompose while a plastic bottle can take around 300 years, leaving behind a threat to nature by being non-biodegradable and toxic.

PROJECT STUDY #002

EBM - Coronet Foods Hattar Solar Park

Our company has successfully manufactured and supplied 25,000 square feet of Eco Pavers for the English Biscuit Manufacturers’ facility in Hattar. This strategic initiative has effectively redirected approximately 18 tonnes of low-value plastic from waste streams and has resulted in an estimated reduction of 62 tonnes of CO2 equivalent emissions, contributing to a cleaner atmosphere.

PROJECT STUDY #003

Open Door Design Studio - Extension Block

We are enabling our building construction industry to use hybrid concrete based building materials like pavers, blocks and tiles which offset plastic via “EcoGrete”. All the products have been extensively tested and deployed across Pakistan and are used in the same way as traditional materials. This intervention at Open Door Design Studio used 1000 blocks for construction and offsets more than 2000 kg of plastic waste and a cumulative offset of 6000 kg of Carbon Emissions.

Detailed Project Studies: USA

In the USA, PolyQor is expanding its footprint, bringing sustainable construction solutions to major urban centres and contributing to the nation's green building initiatives.

PROJECT STUDY #005

#CaliforniaCoastalResilience

A coastal protection project in California, utilising EcoGrete™ for durable and environmentally friendly sea defence structures, safeguarding communities against erosion and rising sea levels.

PROJECT STUDY #006

#TexasIndustrialGreen

Development of a new industrial park in Texas with EcoGrete™, focusing on sustainable warehousing and logistics facilities, reducing operational costs and environmental impact.

Mondelez

945 SQFT PAVERS INSTALLED

945 sqft of pavers transformed the space, reducing 3.46 tonnes of CO₂ emissions.

2023

PepsiCo

Paver 60mm 2810 sqft

A sustainable upgrade with 2810 sqft of pavers, cutting 10 tonnes of CO₂ emissions.

2023

Shell - Meinhardt

Paver and Blocks 60mm, 5 inch 6000 sqft, 500 pcs

6000 sqft of pavers and 500 blocks redefined the landscape, reducing 21 tonnes of CO₂ emissions.

2024

EBM - Headoffice

Paver (+ install) 80mm 24,000 sqft

A massive 24,000 sqft project at EBM’s head office, saving 83 tonnes of CO₂ emissions.

2024

MPCL - AFFCO

Paver 60mm 3500 sqft

3500 sqft of pavers enhanced functionality while offsetting 11 tonnes of CO₂ emissions.

2023

MPCL - AFFCO

Paver 60mm 3500 sqft

Another 3500 sqft of sustainable pavers, achieving a reduction of 11 tonnes of CO₂ emissions.

2023

Artistic Milliners

Paver 60mm 2050 sqft

2050 sqft of eco-friendly pavers boosted durability and reduced 6.93 tonnes of CO₂ emissions.

2023

Shell - Meinhardt

Paver 60mm 1000 sqft

1000 sqft of pavers added strength and aesthetics, offsetting 3.46 tonnes of CO₂ emissions.

2023

Ismail Industries Limited

Paver 60mm 2100 sqft

2100 sqft of pavers elevated the space while reducing 6.93 tonnes of CO₂ emissions.

2023

Our Esteemed Project Collaborators

PolyQor thrives on collaboration. We partner with leading companies and organisations globally, sharing our vision for sustainable construction and working together to bring innovative projects to life. Our collective expertise drives us forward.

These partnerships are crucial to our success, enabling us to scale our impact and accelerate the adoption of EcoGrete™ worldwide.

Partner with Us to Build a Sustainable Future

PolyQor is actively seeking visionary partners who share our commitment to environmental stewardship and groundbreaking innovation in construction. By collaborating with us, you can contribute to a more sustainable world while achieving your project goals with EcoGrete™.

Whether you are a developer, contractor, or investor, let's explore how we can create lasting impact together. Reach out to our team to discuss potential collaborations and start building greener, stronger, and more efficiently.

Greentown Labs, 4200 San Jacinto St, Houston, TX 77004, United States

contact@polyqor.com