Stay Updated: PolyQor News & Media

Discover the latest advancements from PolyQor, your source for pioneering EcoGrete™ product innovations, expanding global collaborations, and key investor updates. Explore how we are building a sustainable future, one breakthrough at a time.

New & Noteworthy From PolyQor

Stay informed with the freshest news directly from PolyQor. We highlight our latest achievements, product launches, and strategic initiatives that are shaping the future of sustainable materials.

Resolving plastic waste crisis in Pakistan

Pakistan generates over 3.3 million tons of plastic waste annually, most of which ends up in landfills, dumped illegally, or litter the countryside and waterways.

Shell Pakistan launches first-ever recycled plastic retail site

KARACHI: Shell Pakistan Limited (SPL) has launched the country’s first-ever recycled plastic retail site, Malik Service Station, on Shahrae Faisal, Karachi.

Dubai Recognizes Sustainability Leaders

The VerdExim Sustainability Awards are instituted by Exim Finance, a Dubai-based finance facilitation company,

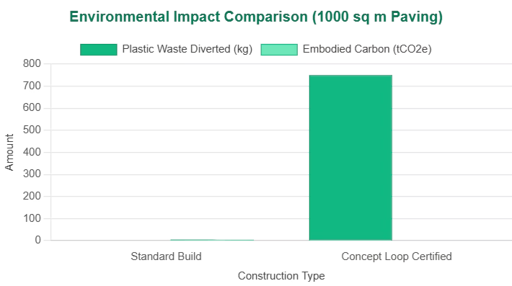

Pak startup Concept Loop bags first prize at Green Tech Hub competition at COP29

Concept Loop, a Pakistan-based startup, emerged as the first-prize winner at the prestigious Green Tech Hub competition at COP 29, capturing global attention for its ingenious approach to tackling plastic waste.

Shell Pakistan celebrates 75 years in Pakistan

The ceremony also included Shell Tameer Awards 2022, a nationwide contest to recognise the best and the brightest young entrepreneurs in Pakistan. This year, over 250 applications were received for the awards programme and 30 finalists .

Closing ceremony for KE’s 3rd edition of KHI Awards held

The KHI Awards was conceived as a platform to bring equity and support for those institutions who are at the forefront of driving societal change.

Celebrating Sustainability Excellence at SDPI's 2024 Awards!

We’re thrilled to share the highlights of Sustainability Awards 2024, a platform recognizing outstanding contributions toward a sustainable future.

Celebrating SDPI Sustainability Awards 2023 Winners!

At SDPI, we're thrilled to announce the exceptional winners of the Sustainability Awards 2023, recognizing outstanding efforts in corporate and CSO sustainability.

Acceleration Challenge

Announcing the 2nd Life Pakistan Acceleration Challenge Finalists! Meet the pioneering teams who have risen above the rest:

PolyQor In Motion: Featured Videos

Immerse yourself in the world of PolyQor through our featured video content. From facility tours to expert interviews and project showcases, these videos bring our mission and innovations to life.

The EcoGrete™ Production Journey

Witness the innovative process behind EcoGrete™, from raw materials to finished sustainable product.

Global Footprint Expands

Our CEO shares the strategic vision for PolyQor and the future of sustainable construction.

Connect with PolyQor on LinkedIn

Join our growing community on LinkedIn for real-time updates, industry insights, and career opportunities. Follow PolyQor to stay at the forefront of sustainable innovation and engage with our team.

Impactful Partnerships & Collaborations

PolyQor believes in the power of collaboration to accelerate global sustainability. We partner with leading organisations, research institutions, and governments to drive meaningful change and scale our impact worldwide.

Academic Institutions

Collaborating on cutting-edge research to advance material science.

Industry Leaders

Forging alliances to integrate EcoGrete™ into large-scale projects.

Government

Working with policymakers to promote sustainable building practices.

USA

Polyqor

Greentown Labs, 4200 San Jacinto St, Houston, TX 77004, United States

Pakistan

Concept Loop

West of the entrance, 7- 2, Sector 17 Korangi Industrial Area, Karachi