Plastic waste is meticulously collected and sorted to ensure only suitable materials enter our process. This crucial first step guarantees the purity and quality of the raw input for our sustainable materials.

PolyQor: Building a Sustainable Future from Waste

Transforming plastic waste into high-value construction materials, PolyQor is pioneering a greener, more sustainable future for infrastructure worldwide.

Our Story: Transforming Plastic Waste into Sustainable Infrastructure

PolyQor was founded by Syed Ali Naqi (CEO), Dr. Sohel Shaikh (CTO) and Aidan deLaunay (CCO) driven by a shared passion to tackle the escalating global plastic crisis. Syed brings a keen entrepreneurial vision, while Dr. Shaikh offers profound chemical expertise, a potent combination that underpins PolyQor’s innovative approach. Their journey began with successful early experiments in South Asia, proving the viability of transforming plastic waste into durable construction materials. This initial success laid the groundwork for PolyQor’s mission to revolutionise the building industry.

A Greener Future, Built from Waste

Core Objective

To convert plastic waste into high-value construction materials, effectively closing the loop on waste and addressing critical environmental challenges.

Visionary Leadership

To be the global leader in sustainable construction materials, driving a truly circular economy for plastic waste on an unprecedented scale.

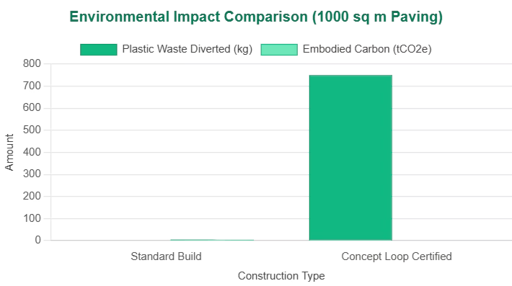

PolyQor’s core objective is rooted in a profound commitment to environmental stewardship and innovation. We aim to convert vast quantities of plastic waste, typically destined for landfills or oceans, into robust and high-performing construction materials. Our vision extends beyond mere recycling; we are dedicated to fostering a global circular economy where waste is not just managed but transformed into a valuable resource, setting a new standard for sustainable development worldwide.

Our Impact in Numbers

Plastic waste saved from landfills and oceans, making a tangible environmental difference.

Contribution to reducing greenhouse gas emissions through our sustainable processes.

Plastic packaging collected and repurposed, preventing pollution and promoting circularity.

Projects completed using PolyQor materials, showcasing real-world applicability.

Meet the Innovators Behind PolyQor

Our founding team represents a powerful combination of deep technical expertise and proven entrepreneurial experience. We share a united vision: to tackle the waste crisis with solutions that are not only impactful but also practical and widely adoptable. This vision, combined with our early successes in the field, drives our mission forward.

Syed Ali Naqi

CEO

Founding & leading multiple tech based initiatives including digital media, IoT, NLP, agritech & clean tech. A strong believer in power of tech to plug any inefficiencies in processes & finding problem statements of complex matrices to align for solution mapping.

Dr Sohel Shaikh

CTO

Sohel brings 20+ years of chemical experience to the team. He specializes in designing innovative chemical processes and has a proven track record of success, including several commercialized solutions. His accomplishments are highlighted by over 100 patents and publications.

Aidan deLaunay

CCO

Background in consulting with a focus on fintech and commercial banking. Brings expertise in go-to-market strategy, unit economics, and financial modeling; and believes the best opportunities lie in bringing efficiency to traditional markets.

Collaborating for a Sustainable World

At PolyQor, we believe in the power of partnership to achieve a truly sustainable future. Our collaborations with leading academic institutions, environmental organisations, and industry pioneers are crucial to accelerating our research, scaling our operations, and expanding our global reach. These strategic alliances enable us to leverage diverse expertise and resources, driving innovation and ensuring our solutions address the complex challenges of plastic waste head-on. Together, we are building a more resilient and sustainable planet.

Innovation in Action: The PolyQor Process

Utilising our patented mix expertise, plastic waste undergoes a unique conversion process. This transforms it into a stable, high-performance polymer base, ready for construction applications.

The converted polymer is then blended with other recycled aggregates and moulded into various construction products, such as bricks, pavers, and panels, ensuring strength and durability.

Every PolyQor product undergoes rigorous quality control and testing to meet industry standards. This guarantees that our sustainable materials are not only eco-friendly but also reliable and safe.

Our finished construction materials are deployed in various infrastructure projects, contributing to reduced carbon footprints and diverting significant plastic waste from landfills and oceans.

Join Us in Building a Better Tomorrow

PolyQor is more than just a company; it's a movement towards a sustainable future. We invite investors, partners, and customers to join us in our mission to revolutionise the construction industry by transforming plastic waste into valuable resources. Your involvement can help us scale our impact, reduce environmental pollution, and create durable, eco-friendly infrastructure worldwide. Let's build a greener, more resilient world, one recycled product at a time.

Greentown Labs, 4200 San Jacinto St, Houston, TX 77004, United States

contact@polyqor.com