PolyQor: Pioneering Sustainable Construction Materials

Revolutionizing the construction industry with advanced, eco-friendly solutions derived from waste.

Revolutionizing Waste Transformation

Our patent-pending process represents a breakthrough in sustainable construction. We transform complex, unrecyclable Multi-Layer Plastics (MLP) – a significant environmental challenge – into high-value construction materials. This innovative approach addresses the growing plastic waste crisis while simultaneously providing a superior alternative to traditional aggregates, marking a new era in material science and environmental responsibility.

The journey from waste collection to the final EcoGrete™ product is a testament to our commitment to circularity, creating a closed-loop system that drastically reduces landfill burden and conserves natural resources.

The Science Behind EcoGrete™:

Enhanced Material Strength

Chemical Bonding Excellence

Our unique process establishes robust chemical bonds between the plastic polymers and inorganic components, ensuring unparalleled material integrity and cohesion. This superior bonding mechanism is critical for the long-term stability and performance of EcoGrete™.

Additives & Coupling Agents

The strategic incorporation of advanced additives, coupling agents, and compatibilisers plays a pivotal role. These enhancements significantly boost the mechanical strength, flexibility, and overall durability of the final material, making it resilient against various environmental stresses.

Superior Mechanical Properties

Through meticulous engineering, EcoGrete™ achieves superior mechanical properties compared to conventional aggregates. This includes exceptional compressive and flexural strength, reduced brittleness, and enhanced resistance to wear and tear, ensuring longevity in diverse construction applications.

Reduced Energy & Environmental Footprint

PolyQor's technology stands out for its significantly lower environmental impact compared to traditional manufacturing processes and alternative waste-to-material solutions.

Low-Temperature Processing

Unlike high-temperature processes that demand substantial energy, our unique thermo-mechanical approach operates at temperatures between 150°C and 250°C. This significantly reduces energy consumption and associated greenhouse gas emissions during production.

Reduced Embodied Energy

The embodied energy per unit of EcoGrete™ aggregate is remarkably lower than that of conventional virgin aggregates. This means less energy is expended throughout the product’s life cycle, from raw material processing to final application, contributing to a truly sustainable building solution.

Cost-Efficient & Sustainable Concrete Alternative

EcoGrete™ offers a compelling value proposition as a direct replacement for natural sand and gravel, providing both economic and environmental advantages.

90%+ Compressive Strength

Achieves over 90% of the conventional compressive strength of concrete made with natural aggregates, ensuring structural integrity and performance.

Lower Dry Density

The reduced dry density of EcoGrete™ leads to lighter concrete structures, potentially lowering transportation costs and structural load requirements.

Reduced Water Absorption

Demonstrates lower water absorption rates, enhancing durability and resistance to freeze-thaw cycles, making it suitable for various climates.

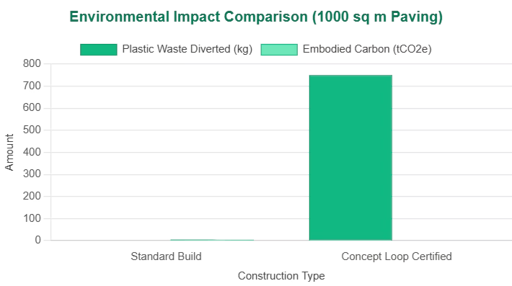

Quantifying Our Carbon Impact

We believe in transparent environmental accounting. We rigorously evaluate the environmental impacts of EcoGrete™ across its entire life cycle, from raw material acquisition to disposal.

EcoGrete™ achieves significant carbon offset primarily through three key mechanisms:

1

Landfill Diversion

By transforming unrecyclable Multi-Layer Plastics (MLP) into valuable aggregates, we divert substantial waste from landfills, preventing methane emissions and resource depletion.

2

Avoided Virgin Aggregate Extraction

The use of EcoGrete™ directly replaces the need for virgin sand and gravel, reducing the environmental impact associated with quarrying, transportation, and processing of natural resources.

3

Reduced Production Emissions

Our low-temperature thermo-mechanical process consumes significantly less energy than traditional aggregate production, leading to a substantial reduction in embodied carbon emissions during the manufacturing phase.

Crucially, EcoGrete™ delivers immediate, quantifiable carbon offset benefits without reliance on ongoing carbonation or chemical processes post-installation.

Outperforming Alternatives: EcoGrete™ vs. Traditional Methods

PolyQor's EcoGrete™ stands as a superior solution in the realm of sustainable construction, outclassing various alternatives across critical performance and environmental metrics. Our technology addresses the shortcomings of existing methods, providing a more efficient, sustainable, and economically viable option for the future of building materials.

We offer unparalleled MLP feedstock tolerance, significantly lower energy intensity in production, and superior scalability, ensuring that our solution can meet the growing demands of the construction industry while maintaining high end-product quality and value. Furthermore, our focus on genuine circularity potential differentiates us from processes that merely delay waste or have limited re-entry into the value chain.

Compared to traditional Supplementary Cementitious Materials (SCMs) like Fly Ash and GGBFS, EcoGrete™ boasts consistent raw material availability, favourable cost trends, and a positive market perception driven by its clear sustainability benefits. When juxtaposed with Recycled Concrete Aggregate, EcoGrete™ shines in terms of feedstock circularity, superior strength and performance, and a streamlined regulatory pathway, backed by its innovative status and strong environmental recognition.

Greentown Labs, 4200 San Jacinto St, Houston, TX 77004, United States

contact@polyqor.com